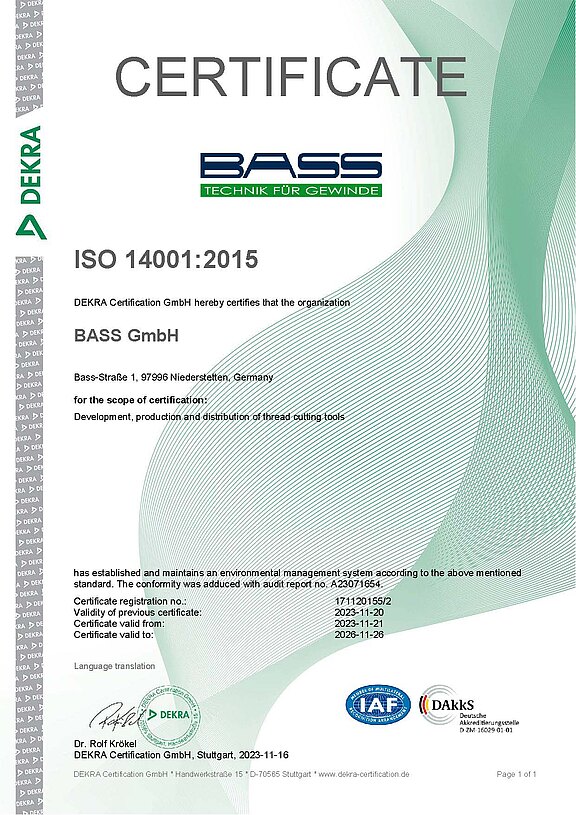

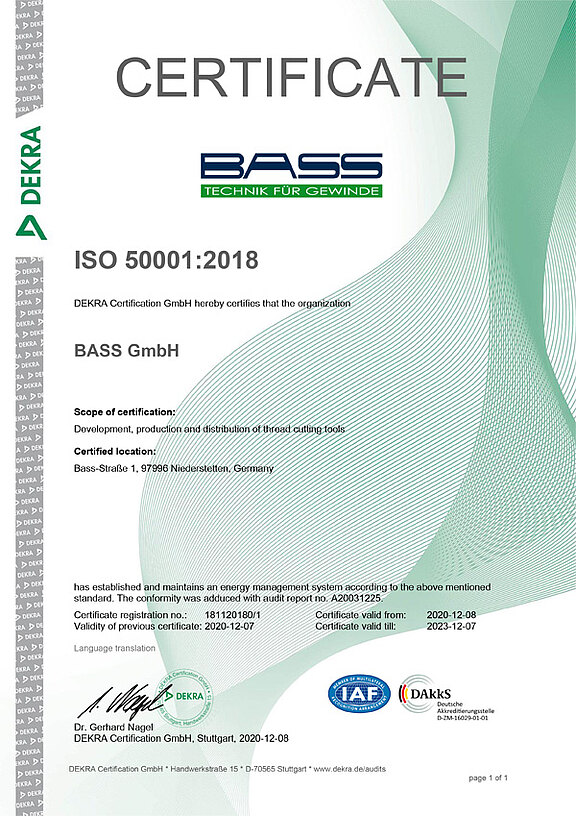

It is our endeavour to make an active contribution to environmental protection and to continuously improve environmental performance. In order to realize these aims we use the most modern process technologies which enable us to minimize or even completely avoid environmental pollution. This is the reason why we also promote environmental awareness to our employees through training and education. Since 2011 our company management has been certified according to ISO 14001, since 2015 also according to ISO 50001.

Our consistent orientation towards environment protection already starts with our company building. It is designed to preserve resources and protect the environment. We use, for example, heat recovery to minimize the use of non-renewable energy, the emissions produced are low due to most modern air filtration and the waste of our oil filtration system is recyclable.

We also value on environmentally-friendly offers by our suppliers. For example we purchase only electricity from renewable energy plants, which do not cause any radioactive waste or CO2 emissions.

In 2007, our company building won the 3rd prize named “Große Nike” in the competition for the best, ecologic concept for an industrial company building in Germany, an architecture prize presented by the Association of German Architects (BDA).

Moreover, through the collection of environmental data, we create the basis for the extensive saving of energy and resources. The analysis of this data enables us to recognize the potential for improvement and to take the necessary measures. Furthermore, updating the data enables us to execute quick but also long-term controls of our efforts in environmental protection.

When producing our tools we always try to consider environmental aspects in order to support our customers to improve their environmental performance, too. An example for this is the investment which we made for the development of rolling taps as well as for the minimum lubrication (MQL) or dry machining.

Also in future we will actively contribute to environment protection because we can only preserve a nice environment for us and future generations if we deal responsibly with resources.

![[Translate to Englisch:] Rückkühlwerk für Nachhaltigkeit in der Energieversorgung [Translate to Englisch:] Rückkühlwerk für Nachhaltigkeit in der Energieversorgung](/fileadmin/uploads/_migrated/pics/Rueckkuehlwerk_klein_01.jpg)

![[Translate to Englisch:] Verteilung und Regulierung der Klimatisierung](/fileadmin/uploads/_migrated/pics/Belueftung_klein_01.jpg)

![[Translate to Englisch:] Wärmetauscher wie eingesetzt zur Kühlung von Ölanlage oder Maschinenpark](/fileadmin/uploads/_migrated/pics/Waermetauscher_klein_01.jpg)

![[Translate to Englisch:] Rückgewinnung von Öl durch auspressen des Schleifschlamms, welcher in Form von Presslingen recycelt wird](/fileadmin/uploads/_migrated/pics/Presslinge.jpg)

![[Translate to Englisch:] Entfall von Etiketten durch direkte Laserbeschriftung der Verpackung](/fileadmin/uploads/_migrated/pics/Laserbeschriftung_klein.jpg)

![[Translate to Englisch:] Erhöhung des Wirkungsgrads durch Kühldüsennachführung](/fileadmin/uploads/_migrated/pics/Nachfuehrung.jpg)