Filigree components are part of our life. Ranging from the watch on your wrist through spectacle hinges and the braces of our children up to ubiquitous electrical components. They are part of our daily life.

The wide range of applications comes along with various materials: titanium, nickel, tungsten heavy metals but also non-ferrous metals like brass and copper alloys or nickel silver.

The corresponding M1 up to M3 (or UNC/UNF No2 to No5) threads in the workpiece are as filigree as the components themselves, however, do not take second place to their bigger brothers when it comes to processing complexity.

For a variety of thread types, BASS offers suitable solutions that are directly available from stock including tools for the machining of materials with a hardness of 63 HRC.

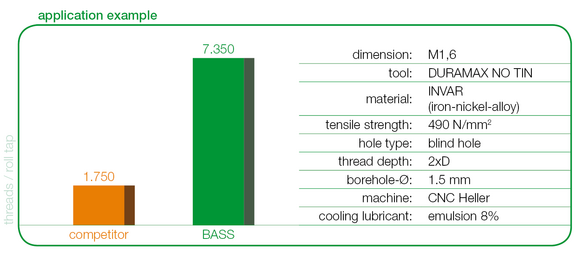

Despite their small dimensions, tools like the roll tap DURAMAX NO TIN in M1 score high with a high tool life and process-reliable machining.

Quite similar to the cutting tap DOMINANT HZ38 HL in M2: in spite of the small tapping space, thread depths up to 2.5xd are only one application example for this small tool.

The thread milling cutter GFD ensures maximum concentricity even from dimension M1.2 onward.

When machining with cutting taps and roll taps, BASS recommends to use the tap holder HST SYNCHRO 10 which is specially designed for small dimensions. The reason is that due to the small tool dimensions, even small synchronization failures of the machine may be punished with tool breakage.

Through the length compensation acting on compression and expansion of 0.4 mm, thus amounting to the total standard pitch of a M2 into both directions, synchronization failures are completely compensated providing for a process-reliable machining.

Small but powerful – the BASS threading tools from M1.