one profile – many thread types

The 60°-profile can be found in many thread types. In metric and metric fine threads, in UN-threads as well as in the American pipe thread types NPSM and NPSF.

MJ, UNJC und UNJF, however, are special types of threads. In these threads, the flank diameter of 4H is closely tolerated to guarantee a greater overlap of internal and external thread.

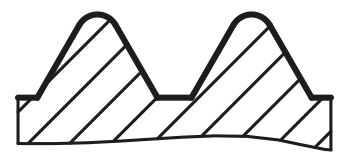

rounded thread profile

The main difference, however, is the thread profile which is generally rounded in J-threads whereas the “standard profile” has comparably sharp-edged corners. These corners of the part create the risk of cracking in case of high load. Especially in the aerospace industry there are enormous quickly changing forces involved that put the vibration resistance of the components to the test. The linked risk of cracking is tremendously reduced by J-threads.

highest demands

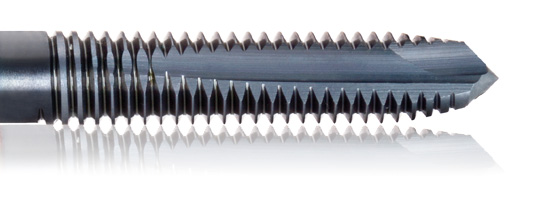

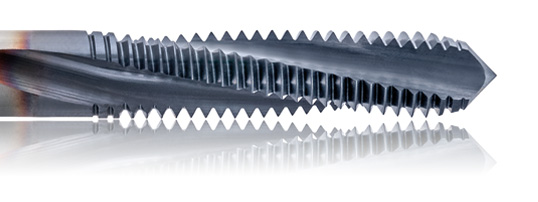

What’s more, there are special materials with highest demands on mechanical resistance, weight and corrosive resistance used in the aerospace industry. These materials are also favorably used in vehicle engines and other components with high performance requirements and are regarded as difficult to machine. This is why our threading tools with J-profile furthermore have special geometries that ensure a process reliable machining.

standard and on stock

A wide range of MJ-, UNJC- and UNJF-threading tools held in stock can already be found in our catalogue program. As a standard, our tools for the machining of through and blind holes are available in powder metal but can also be obtained in solid carbide upon request.

extract from the catalogue programme

VARIANT TIH TICN

- catalogue tool

- for the machining of highly tempered steels up to 45 HRC, titanium and titanium alloys

- for through holes up to 3xD

AVANT TIH13 TICN

- catalogue tool

- for the machining of highly tempered steels up to 45 HRC, titanium and titanium alloys

- for blind holes up to 2,5xD

VARIANT NI TICN

- catalogue tool

- for the machining of highly tempered steels up to 48 HRC, nickel and nickel alloys

- for through holes up to 3xD

AVANT NI13 TICN

- catalogue tool

- for the machining of highly tempered steels up to 48 HRC, nickel and nickel alloys

- for blind holes up to 2,5xD

![[Translate to Englisch:] BASS Luftfahrtkatalog](/fileadmin/uploads/02_service/downloads/thumbnails/aerospace.jpg)